Your challenges

Meeting today’s standards while preparing for tomorrow means tackling persistent water-related issues, including:

Complying with strict environmental discharge limits

To avoid permit violations, complying with local regulations ensures continuous operations.

Removing persistent micropollutants, heavy metals and PFAS

Your mining wastewater contains heavy metals, and trace chemicals from several streams.

Reducing water consumption and maintaining water quality

To ensure safe, and reliable water reuse for operations, overall reduction of water will help meet your sustainability goals, while managing large volumes of process water and wastewater.

Enhancing mining recovery

There’s still value left in wastewater such as precious metals which can be recovered.

How can the Saur group, together with its entity Nijhuis Saur Industries, meet your needs?

We’re committed to giving water the value it deserves in mining and mineral processing. Our solutions are built around your operations and environmental goals, with an emphasis on the 4R strategy: Reduce, Remove, Reuse, and Recover.

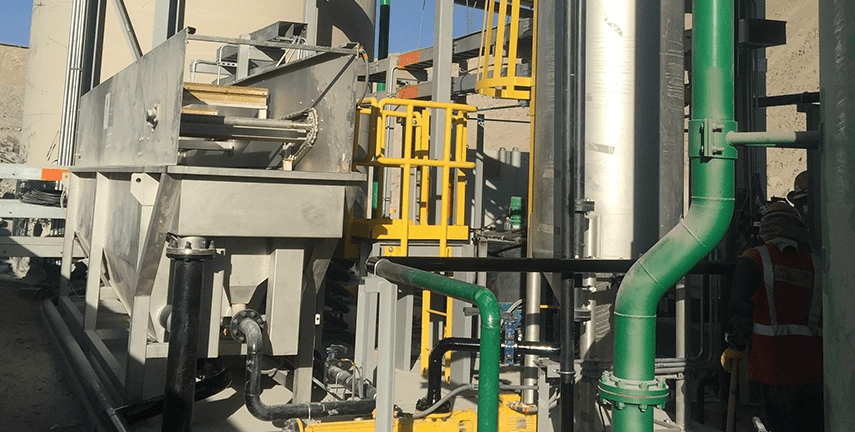

- Design and build tailored water and wastewater treatment plants for greenfield or existing sites

- Reduce operational water demand through reuse and process optimization

- Remove harmful contaminants and improve water quality for discharge or reuse

- Recover valuable materials and energy from wastewater and sludge

- Minimize your environmental footprint while ensuring regulatory compliance

Water sources and wastewater composition in mining operations

In mining operations, water comes from several sources.

The most common is groundwater, which is pumped from below the surface to support mineral extraction and processing. Increasingly, mining companies are exploring alternative water sources, such as treated wastewater or desalinated seawater, to reduce pressure on freshwater resources and improve sustainability.

Freshwater sources like rivers, lakes, and reservoirs are also used, particularly in regions where surface water is readily available. However, reliance on these sources can lead to conflicts with local communities and ecosystems, especially in water-scarce areas.

Wastewater from mining operations contains a complex mix of pollutants.

It often includes suspended solids like sand, silt, and fine mineral particles from crushing and grinding processes. Heavy metals such as arsenic, mercury, and lead can be present, depending on the mined material. Chemical residues from ore processing, including cyanide, acids, and flotation agents, are also common. In addition, salts, nutrients, PFAS and hydrocarbons may be found, requiring advanced treatment before reuse or discharge.