Your challenges

From start to finish, we have sustainable and innovative water solutions to all your challenges.

Reducing water intake / safe ingredient water: zero consumer health impact

Pharma and cosmetics manufacturers must ensure the highest water purity standards, as water is often a direct ingredient. Any contamination risk can compromise product quality and consumer safety. Simultaneously, reducing water withdrawal from sensitive sources supports sustainability and business continuity.

Reducing discharge cost / meet upcoming regulations

Wastewater from these industries may contain complex organics, solvents, or micro-contaminants. Without proper treatment, discharge fees can be substantial—or regulations may soon require advanced treatment systems, forcing costly upgrades or plant modifications.

Reducing water cost and focus on water stewardship to meet sustainability goals

With rising water tariffs and increasing pressure to demonstrate environmental responsibility, companies face the challenge of reducing water use. Reuse of process water for cleaning, utilities, or even ingredient-grade applications can significantly cut costs and improve ESG performance.

Missed opportunities to get more value out of your wastewater

Pharmaceutical and cosmetic production generates wastewater that can still hold residual energy or valuable compounds. Technologies for heat recovery, biogas generation, or extraction of organics can transform this waste stream into a source of added value, supporting circular economy ambitions

How can the Saur group, together with its entity Nijhuis Saur Industries, meet your needs?

We have decades of experience in meeting USP, PhEur, JP and other global pharmacopeia regulatory requirements for Water for Injection (WFI) applications. We’re also experts with equipment to produce Purified Water (PW) for non-compendial applications.

Our expertise in wastewater come from our extensive list of global installations that are delivering consistent results.

- Construct a complete process water or wastewater treatment plant

- Reduce water consumption

- Remove pollutants and contaminations

- Reuse water for improving footprint of the facility

- Recover valuable resources

- Minimize the ecological footprint of water usage

Pharmaceutical and cosmetic types of water

Process water

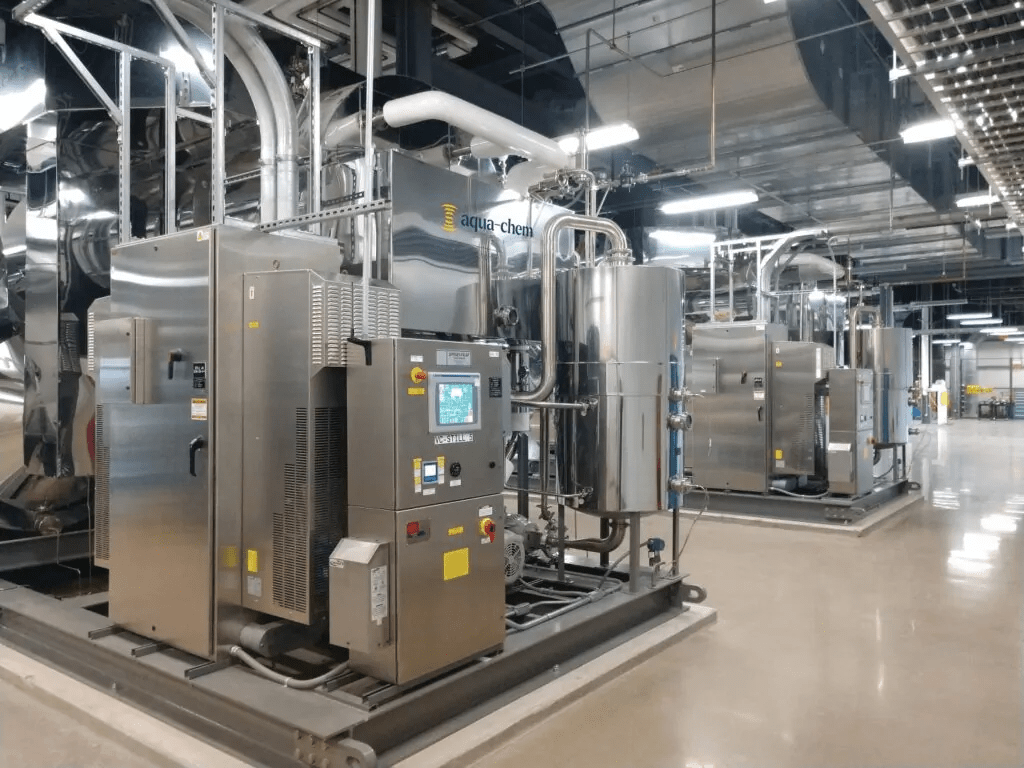

Our systems deliver consistent and reliable water quality and quantity to meet your production needs, while meeting strict parenteral standards, including:

- Smart design features contribute to higher operating efficiency and less downtime for maintenance and cleaning.

- Effortless Integration into existing systems thanks to our field tested and thoughtful design approach.

- Quality construction with a track record of performance and reliability.

Solutions:

- Turnkey Water Rooms

- Water for Injection (WFI) Generation & Distribution Systems

- Purified Water (PW) Generation & Distribution Systems

- Hot Water Sanitizable Reverse Osmosis (RO) Filtration

- Pure Steam Clean Steam Generators

Wastewater

Consistent and reliable water quality and quantity production to meet your production needs and discharge compliance, while meeting strict standards, including:

- Revamping of underperforming wastewater treatment plants for better Life Cycle Analysis (LCA).

- Meeting the quality standards to convert WWTP effluent into safe river discharge, irrigation water, or even drinking water for internal reuse.

- Removing PFAS, solvents, PIE, hormones and other persistent micropollutants from wastewater.

Solutions:

- Pretreatment

- Biological Treatment

- Tertiary Treatment

- Sludge Management