Your challenges

Increased turbidity during heavy rainfall

Sludge from extended aeration is poorly fermentable. This limits biogas yields and reduces the value of digestion. DIGESTHANE® enhances sludge biodegradability

Optimizing renewable energy generation

Biogas recovery is a strategic lever to reduce plant energy dependence. Sludge-to-energy conversion must be maximized. DIGESTHANE® meets this goal by boosting methane production.

Reducing sludge volume for disposal

Minimizing digested sludge reduces treatment, transport, and disposal costs. Stabilizing organic matter while cutting final residue is essential. This requires a process that delivers both performance and efficiency.

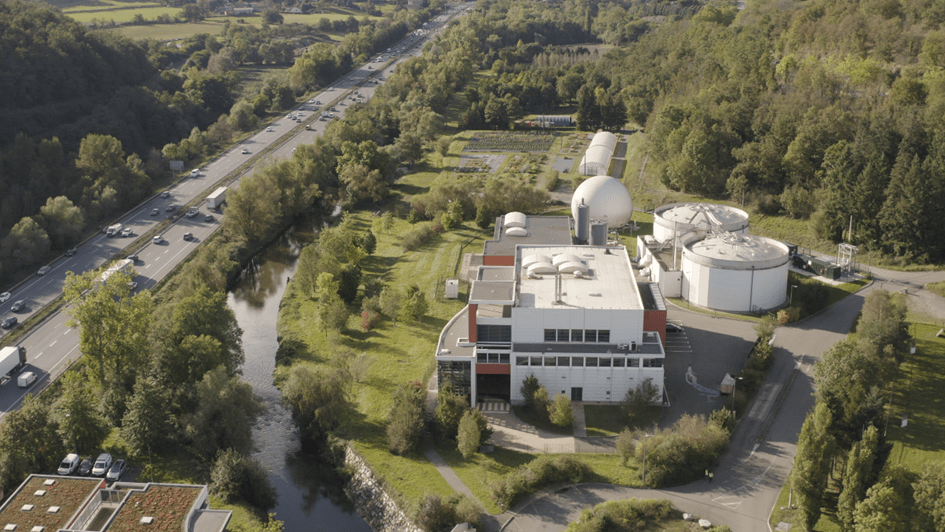

Adaptable to existing treatment plants

Many existing facilities aren’t designed for anaerobic digestion. DIGESTHANE® enables integration of energy recovery even in such cases. A sustainable upgrade opportunity for municipalities.

How does it work ?

Disruption

DIGESTHANE® begins with sludge sonolysis in the SONOFLUX® reactor, where ultrasound breaks down biological cells and releases digestible intracellular material.

Digestion

The pretreated sludge undergoes anaerobic digestion, enabling methanogenic bacteria to process it more efficiently.

Performance

This two-stage process accelerates hydrolysis, boosts biogas production, and significantly reduces sludge volume.

Our positive impact

Learn more

Enhanced energy production

DIGESTHANE® boosts biogas output for use in cogeneration or sludge drying. It transforms sludge into a local energy resource. A strategic solution for energy transition targets.

Sludge reduction

Better organic matter breakdown means less residual sludge to manage. This reduces operational costs and environmental impact. A concrete response to waste management challenges.

Compatible with existing plants

Sensors used (notably the NH4+ probe) are robust and low-maintenance. The AMMONAIR® algorithm constantly adapts aeration settings. Even in sensor failure, fallback modes ensure effective control.

Proven and modular technology

SONOFLUX® reactors are coupled with insulated, mixed digesters for optimal performance. Installations are flexible and modular, suited to various sludge types. DIGESTHANE® is already operational at multiple sites in France.

Key figures

Up to 30%

Less digested sludge thanks to improved digestion efficiency

More than 20%

Increase in biogas production using SONOFLUX® ultrasonic pretreatment

25 - 40%

Reduction in retention time in the digester, depending on sludge characteristics