Your challenges

In a context of fragile resources, increasing turbidity in surface waters, and growing needs for sanitary security, ultrafiltration addresses several key challenges.

Producing high-quality water from degraded sources

Ultrafiltration is especially suited for turbid or sensitive water sources. It provides a reliable physical barrier against microorganisms and particles—without the use of specific chemicals.

Ensuring water safety and compliance

With proven efficiency (> 6 log for bacteria, > 4 log for viruses), ultrafiltration meets the most stringent health standards for drinking water or high-quality industrial water.

Reducing operational costs

Thanks to polyethersulfone membranes—resistant to bacterial attack and easy to clean—ultrafiltration in dead-end mode allows for optimized operations, with minimal maintenance and long-lasting performance.

Securing downstream processes

Used as a pretreatment before reverse osmosis (e.g., for desalination), ultrafiltration protects finer membranes downstream and improves the overall performance of the treatment line.

How does it work ?

Process

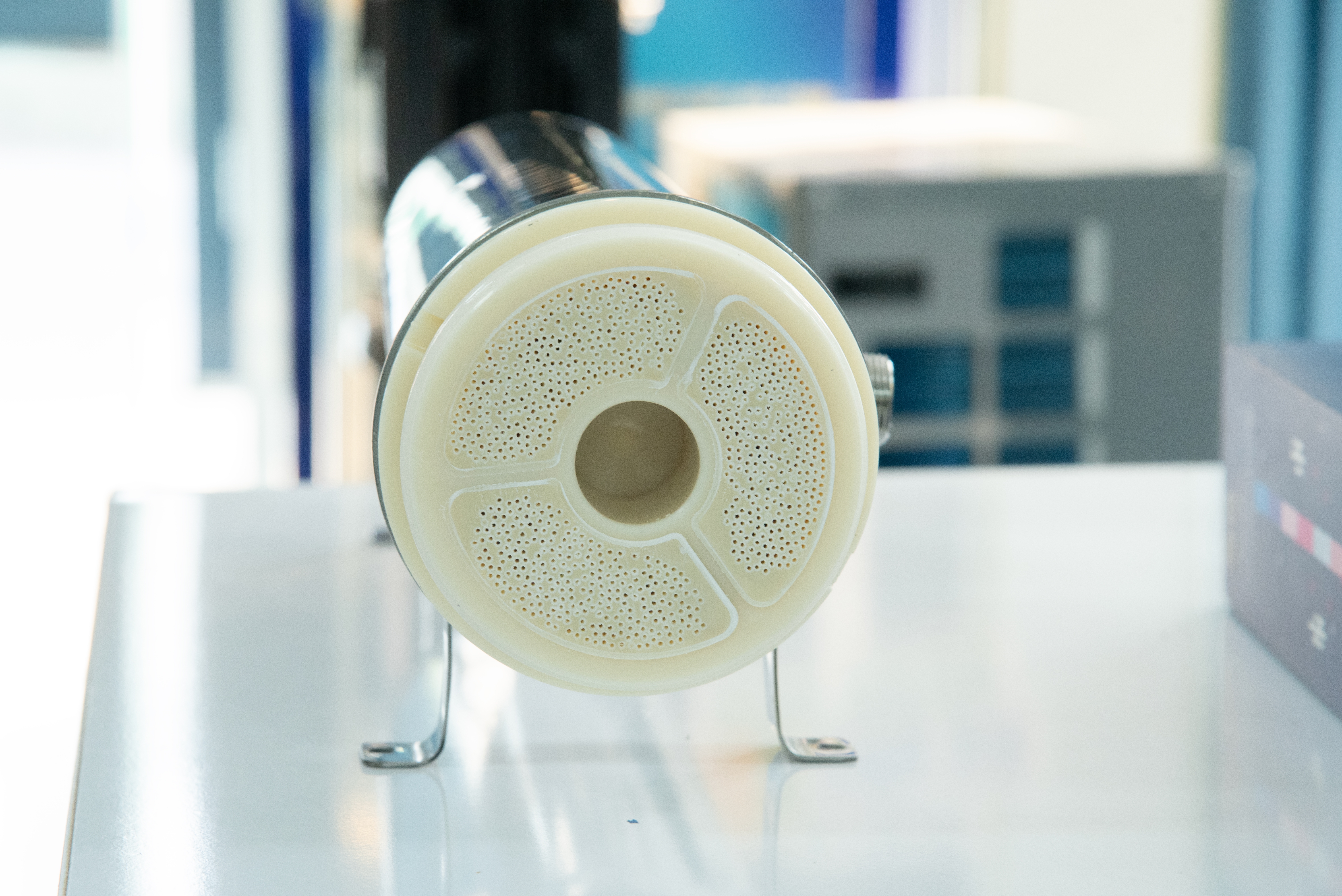

Ultrafiltration uses microporous membranes (1–100 nm) that block viruses, bacteria, and colloids, while allowing water and minerals to pass through.

Integration

The system can be installed in either horizontal or vertical configurations, depending on site constraints, and is suitable for drinking water treatment lines or water reuse projects.

Autonomy

Operating under low pressure, the system does not require specific detergents for cleaning—reducing industrial discharges and simplifying daily operation.

Our positive impact

The use of ultrafiltration improves water quality, secures drinking water supply, and helps reduce the environmental footprint of water treatment facilities.

Enhanced sanitary protection

A well-controlled and reliable barrier treatment, even under high turbidity conditions.

Reduced chemical inputs

Cleaning without specific detergents, minimizing industrial discharge and protecting aquatic ecosystems.

Improved system reliability

By acting as a constant and predictable physical barrier, ultrafiltration stabilizes performance and reduces risks linked to raw water variability.

Versatility across applications

Whether for drinking water, industrial or agricultural reuse, or as a pretreatment for reverse osmosis, ultrafiltration fully supports a circular water management approach.

Key figures

Pore size: 1–100 nm

Effectively filters colloids, macromolecules, viruses, and microorganisms

>99% removal rate

Viruses and bacteria eliminated through physical membrane ultrafiltration

30,000 m³/day

Capacity of the Louvigny plant (Calvados) using ultrafiltration technology